Activities

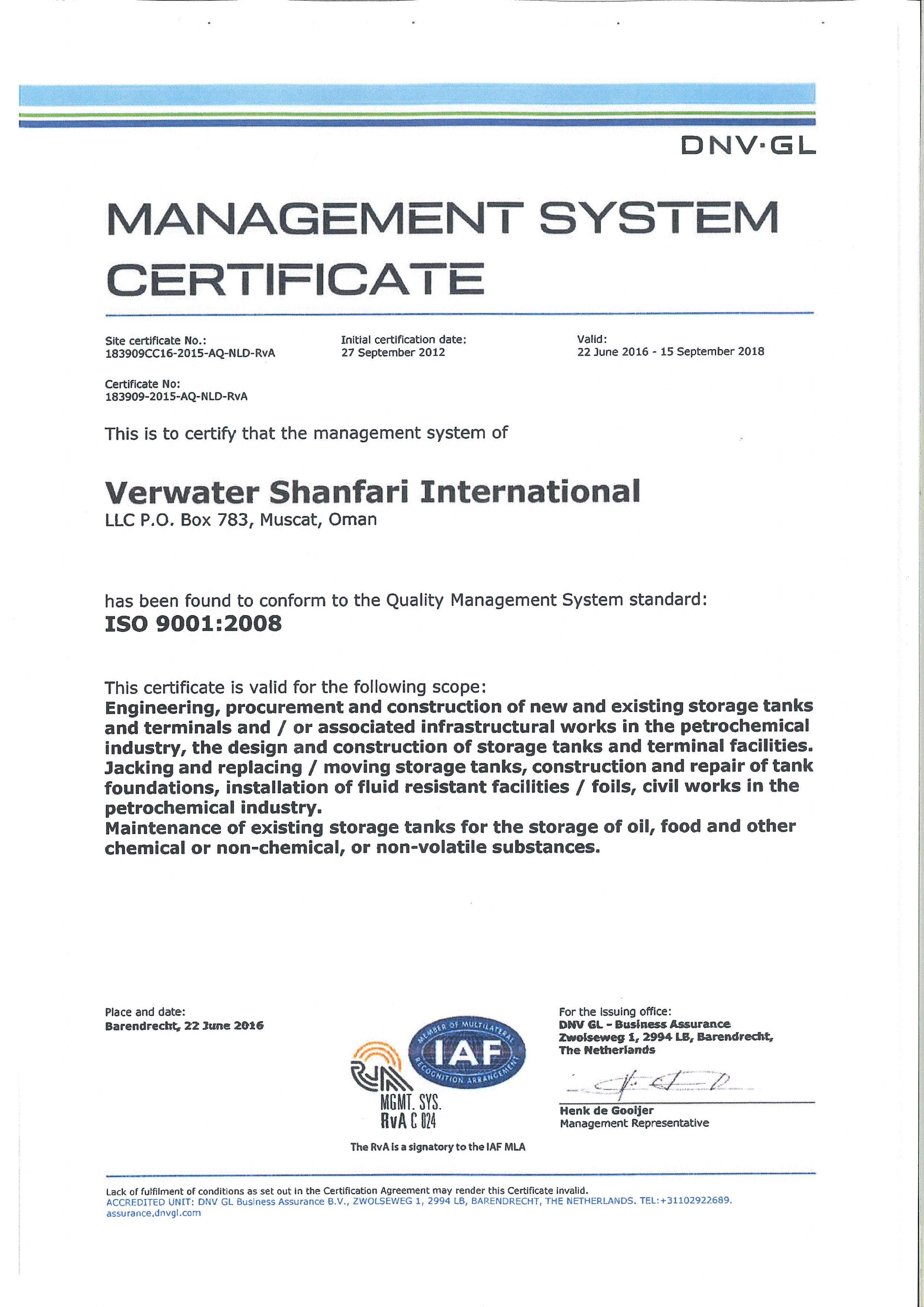

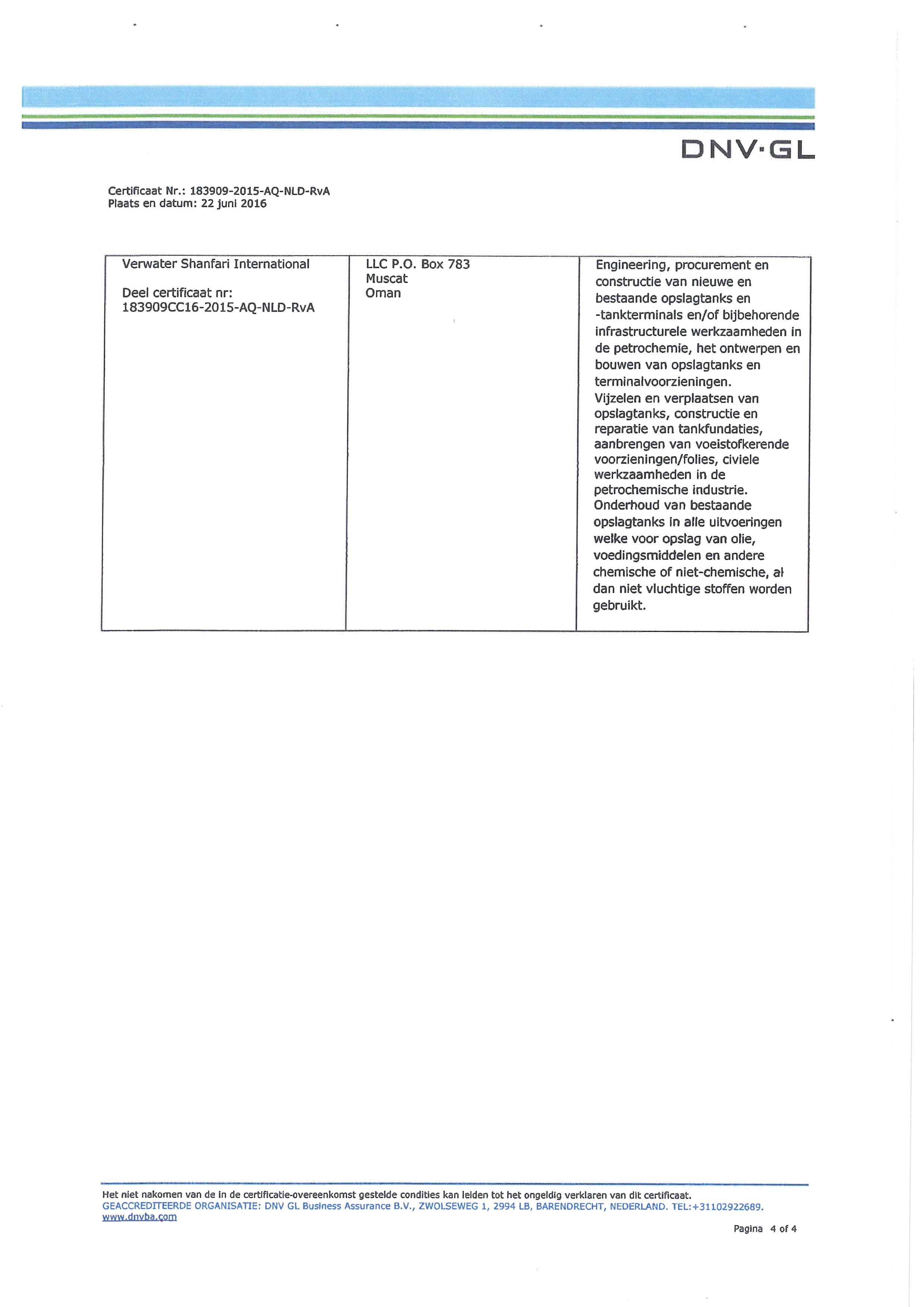

VERWATER SHANFARI INTERNATIONAL LLC with their Head Office in Muscat Oman will offer excellent service in the engineering, design, procurement, project management, project controls, construction and construction management, quality assurance and quality control in the field of Total Tank Maintenance and Tank construction works.

From their Head office in the Netherlands, Verwater Group can support Verwater Shanfari International in total tank maintenance and total tank terminal construction. A dedicated team of over 750 employees works to provide excellence, safety and quality. From our Head office in Rotterdam the Netherlands we meet the demands for specialized projects worldwide.

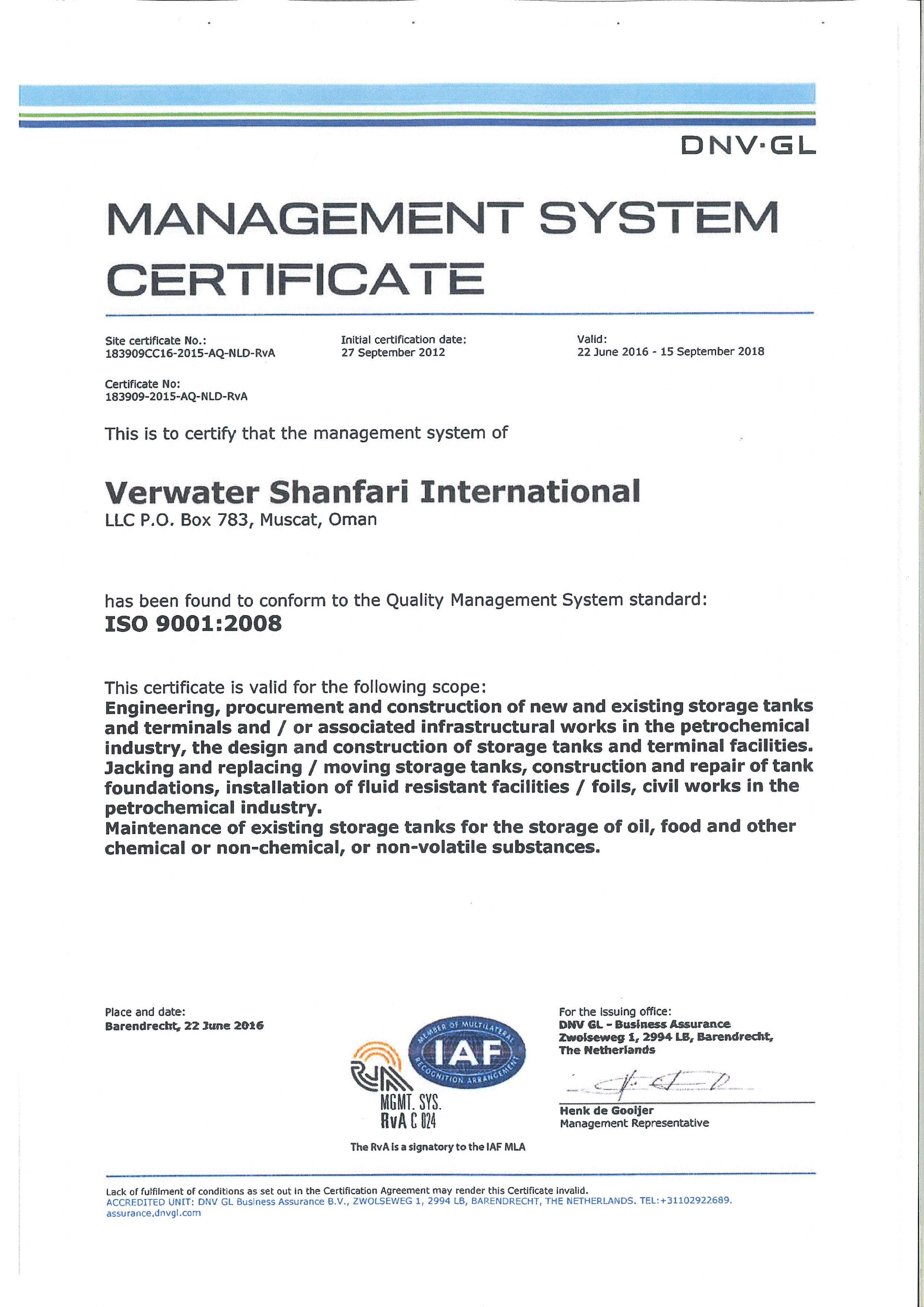

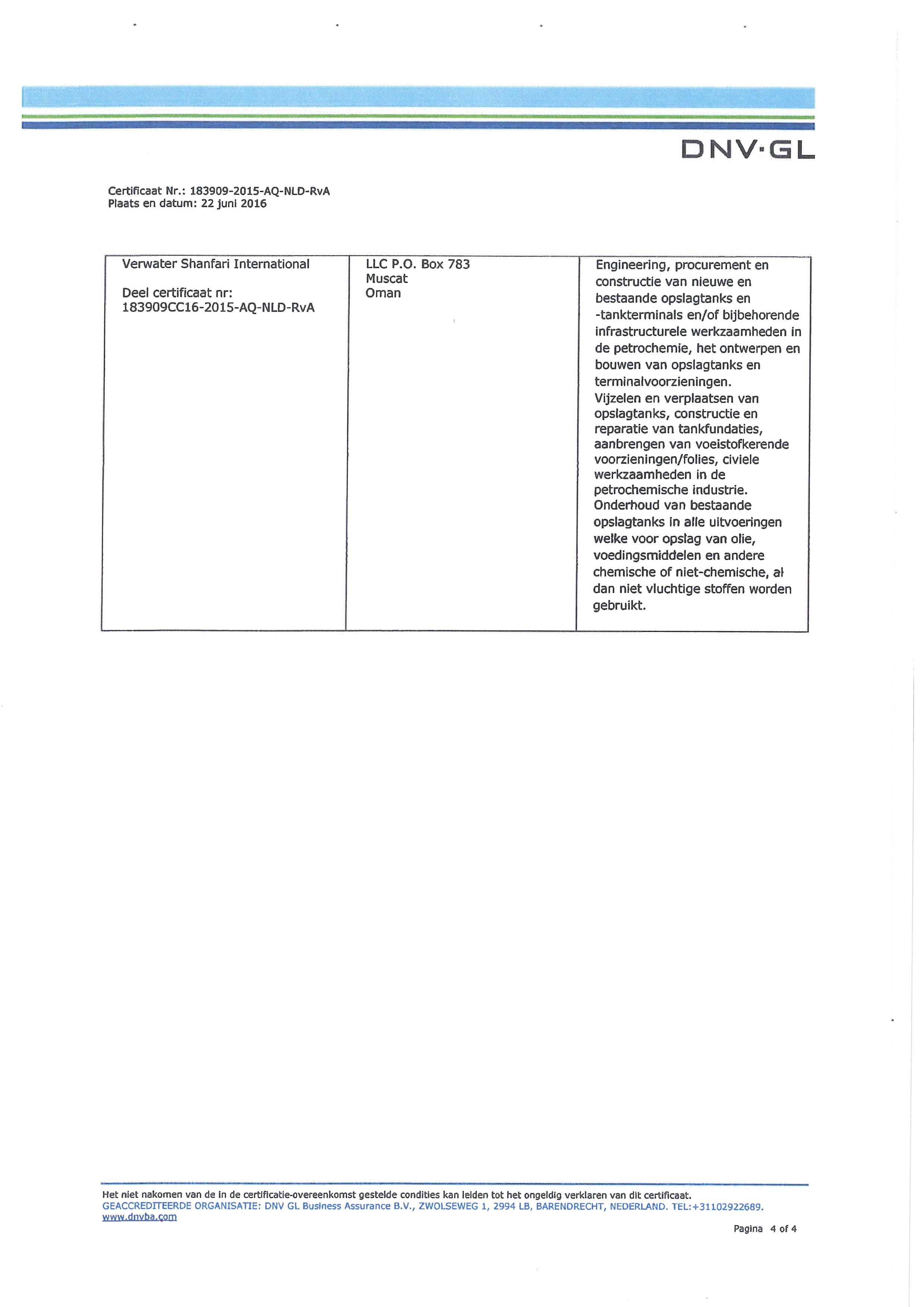

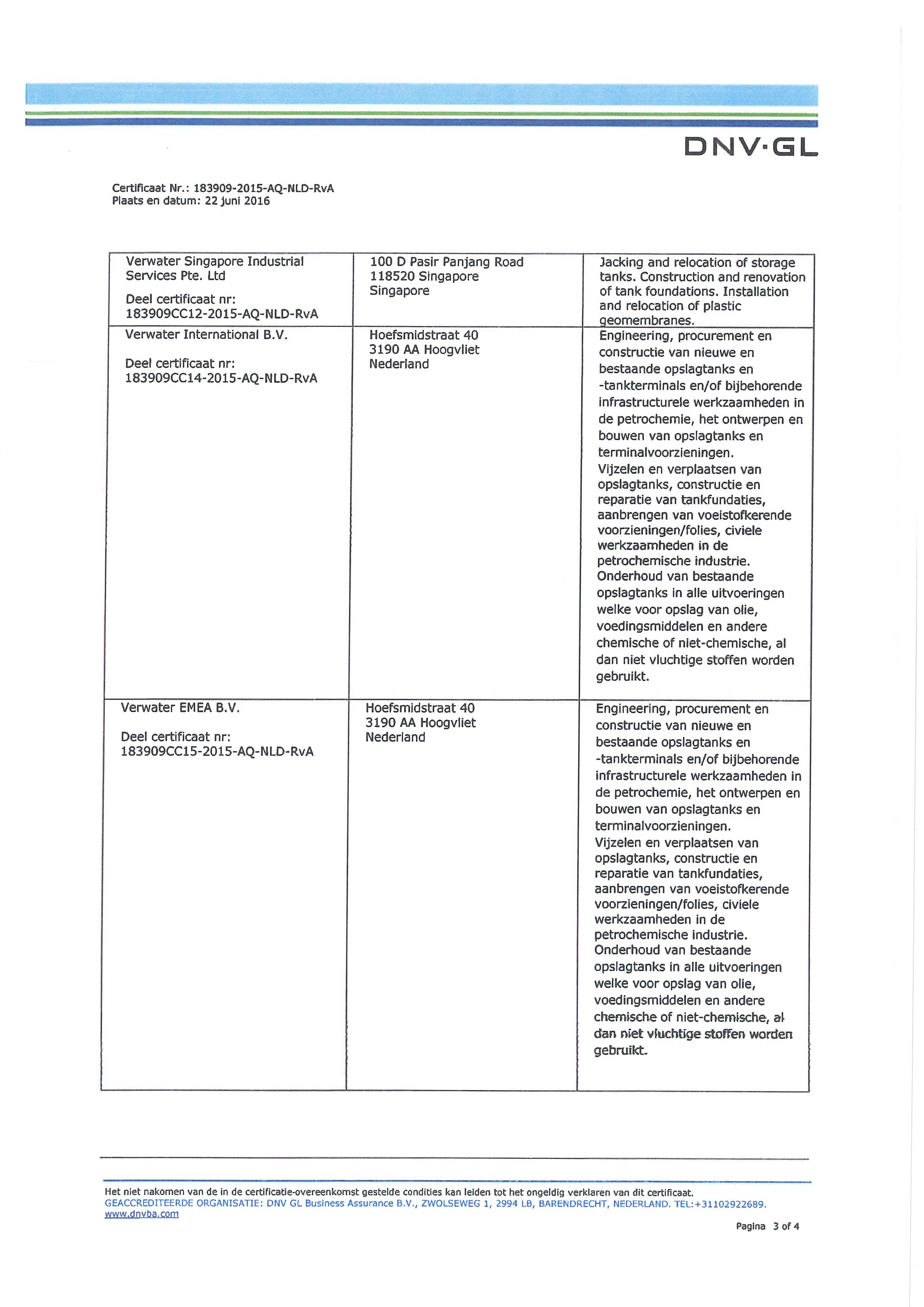

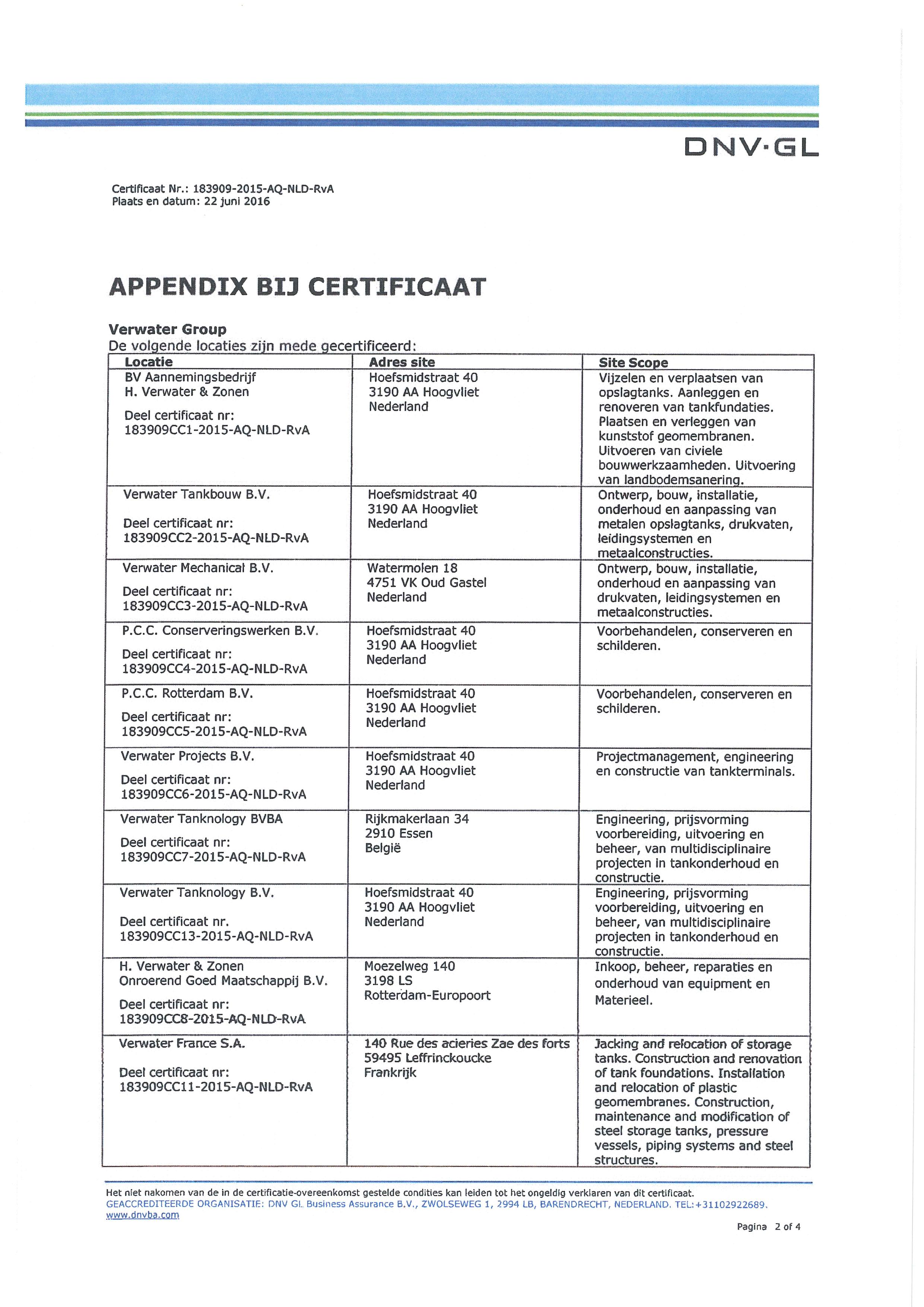

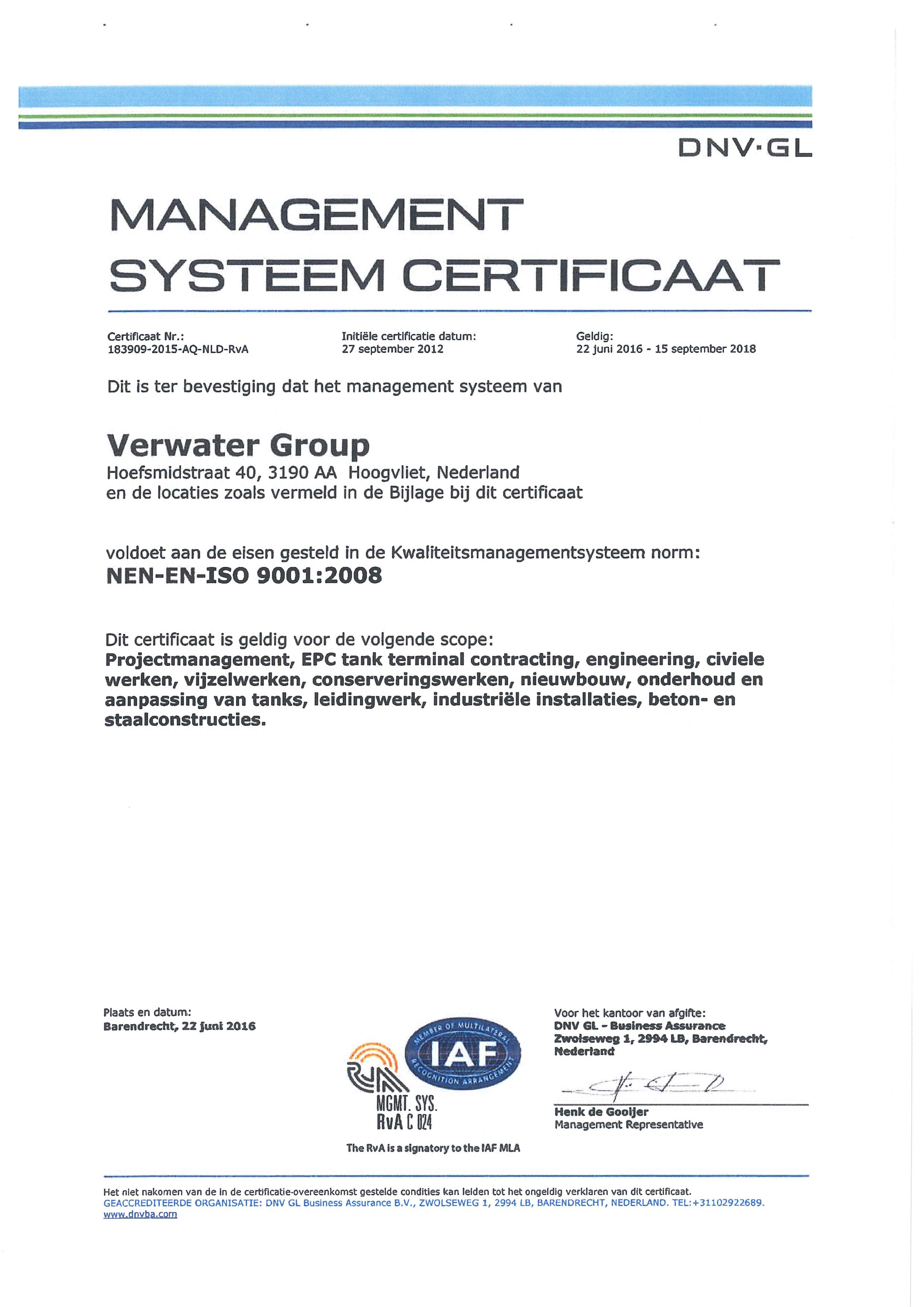

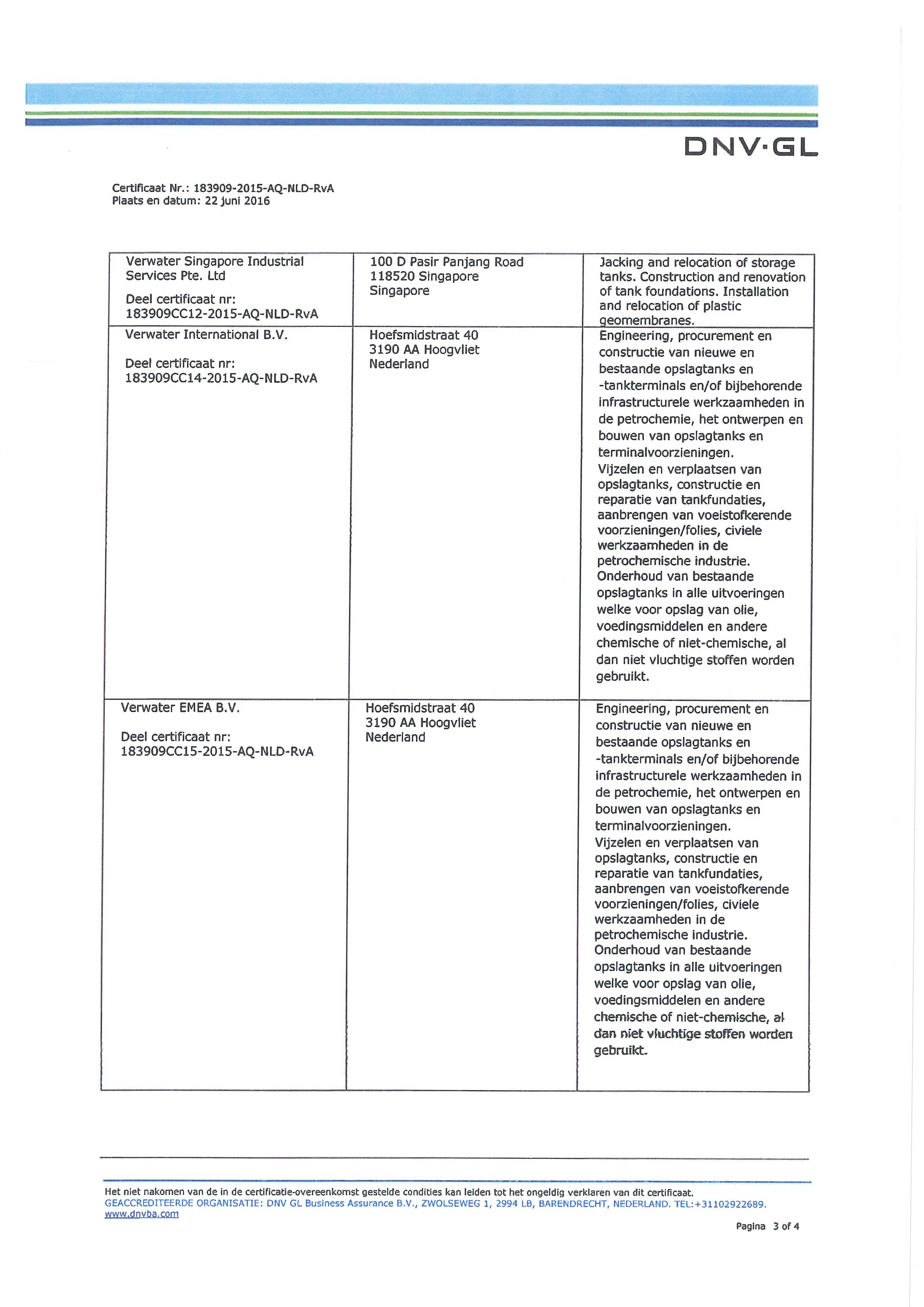

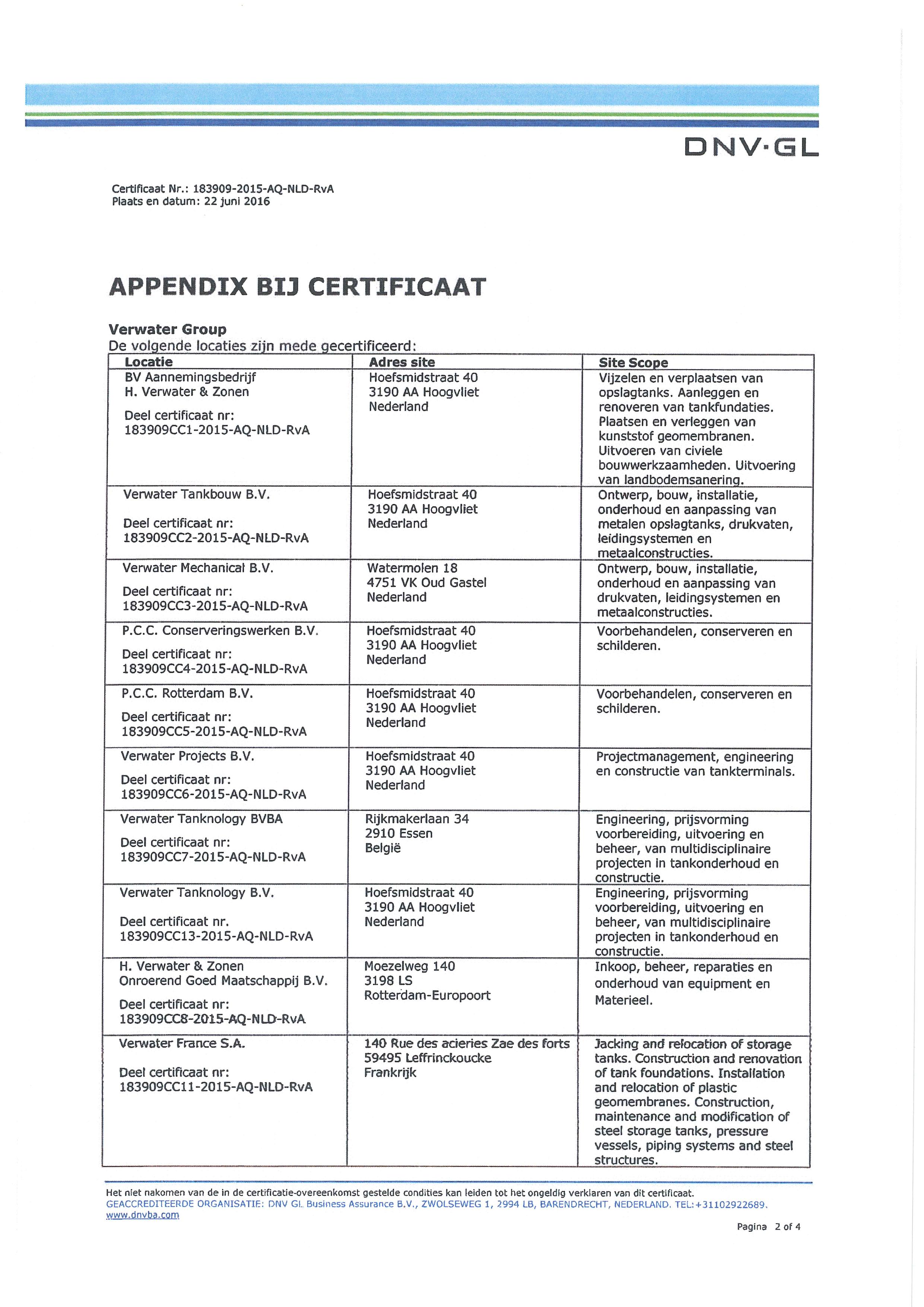

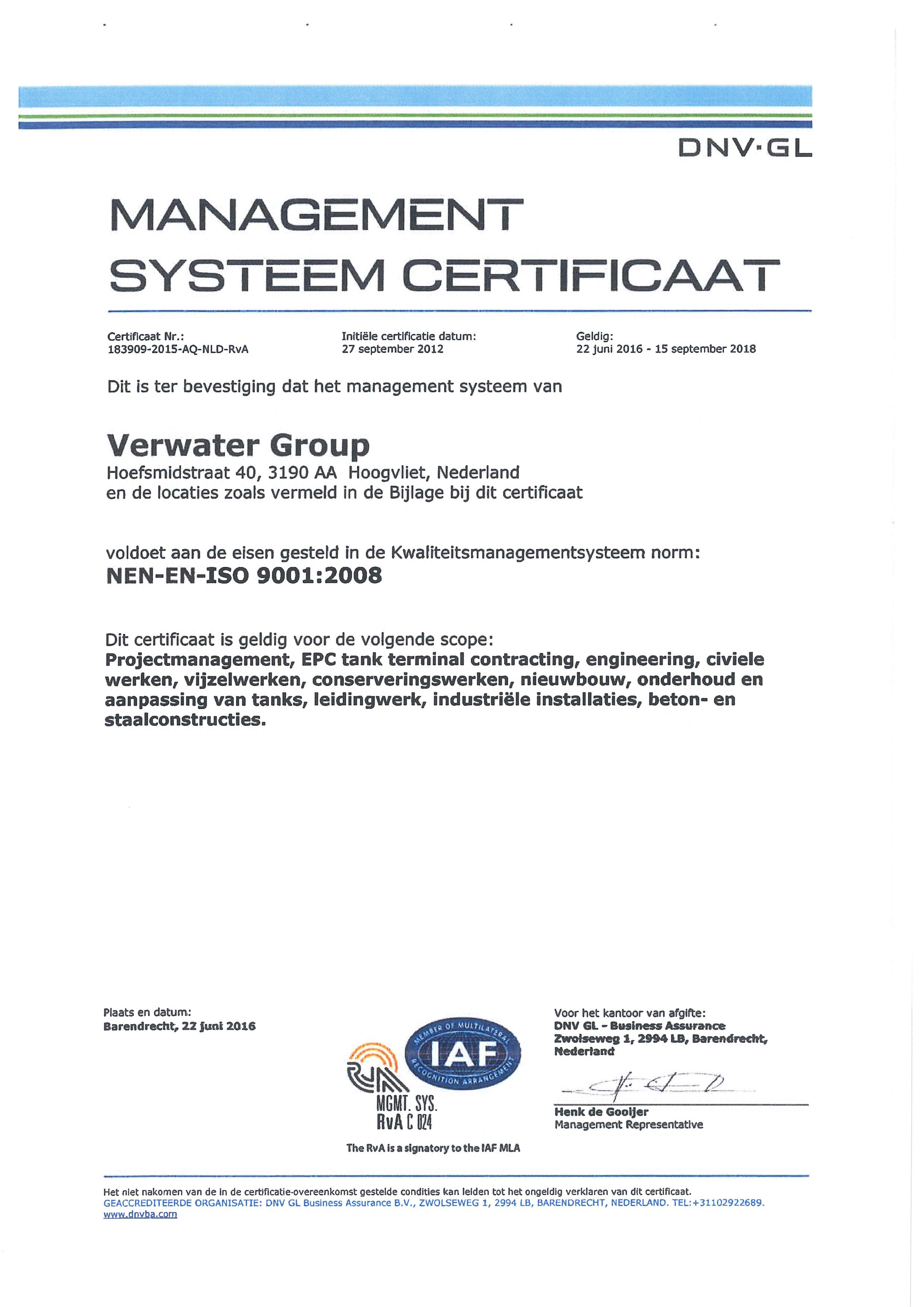

The policy of the group is focused on fulfilling all requirements concerning quality, environment and safety. The systems and procedures are designed to maintain and improve these aspects and are therefore given high priority. Verwater has been assessed and approved in accordance with ISO 9001 : 2008 en SCC-P.

Verwater is the right partner for total terminal construction. With six complementary divisions the company is able to deliver complete storage plants.

The engineering division focuses on the design and engineering of safe and functional storage tanks. For the design and engineering of piping, tanks or other structures the latest technology is used. 3D modeling and complex stress calculations ensure a safe and efficient construction process at any time.

The division for tank construction provides durable solutions to occurring problems such as leakages or foundation settlement. With Verwater’s unique jacking system the company is able to life and move tanks of all sizes.

The construction of tank pits, leakage detection systems and infrastructural works on plants is the responsibility of Verwater’s civil department. Highly skilled employees with a vast amount of experience carry out complex measurements with the latest software programs.

An important division of Verwater that makes sure the tank and its surrounding infrastructure meet all requirements.

The tank construction department is responsible for the actual erection of storage tanks. Apart from these tanks the division also builds roof tops of any type and size. In its own workshop Verwater constructs prefabricated pressure vessels and small tank that can easily be installed on site.

The piping division specializes in engineering, manufacturing and constructing piping installations. Verwater’s piping department uses the highest quality of materials such as GRE, steel or PE pipes. These pipes are prefabricated in Vermater’s workshop and easily installed on site.

P.C.C. Conserveringswerken, Verwater’s coating division, finishes the job with the application of different layers of professional coating on the tanks. The combination of experienced tanks. The combination of experienced professionals and the latest equipment ensures a sustainable solution to any surface problem.

All of these disciplines are utilized worldwide. With offices around the globe Verwater really put its mark on the industry. From East to West, Verwater is recognized as a skilful and reliable partner.

In tank maintenance Verwater plays a key role . The importance of well maintained tanks is growing steadily due to increasing safety and environmental requirements, higher quality standards as well as more economical use of tanks. The experience of Verwater in every aspect of storage tanks results in the most beneficial maintenance methods. Verwater offers a complete package for every total tank maintenance project, by applying the most modern techniques in jacking, shotblasting & painting, soil cleaning, repair of tankbottoms, mechanical work and high pressure water cutting.

Tank jacking is an indispensable specialism that facilitates a range of works varying from mechanical tank repairs to complete tank refurbishments. Thousands of tanks have been successfully jacked and repaired thanks to Verwater’s unique jacking methods. No matter what size or type, there is a safe jacking method for every tank.

Steel storage tanks as used on refineries and storage facilities for the storage of liquids are rarely constructed on piled foundations made of sand, crushed stone or a combination of both. If the sub soil is weak and easily compressed settlement of the foundation under the tank may occur. These settlements can be evenly or unevenly. If it becomes excessive problems may arise with the floating roof, the bottom and the pipes to and from the tank. If the tank settles below ground level corrosion may occur as a result of contact with water. In each of the above cases Verwater is able to reinstate the foundation to an acceptable.

The high pressure water cutting and blasting techniques are getting more common in the petro chemical industries. This method meets the demands of higher safety requirements and more stringent laws for the employment conditions. Where traditional techniques are no more applicable because of fire – and explosion hazards, hydrocutting is a safe solution to demolish old tank bottoms.

Each type of tank requires a different technical approach. Extensive experience combined with the latest computing methods results in the safest, most efficient technical solutions.

All designs and analysis comply with international standards for tank construction and repair. Tank and repair design is an in –house activity which contributes to high quality projects. Also design of piping with modern tools such as 3D modeling is part of Verwater’s services. National and international requirements are implemented in our designs and repairs. In depth knowledge (Tanknology) of these codes results in optimum designs.

The engineering department offers the following services:

The repair of tanks , in combination with tank lifting , requires extensive analysis in order to work safely .Final Element Method (FEM) stress calculations are made in computer simulations.

Survey reports are generated , showing factual and visually that repair systems stay within limits.

One of the storage tanks . Not only in tank design but also in civil works and all tank related works. Employees working more than 20yrars in this field are available for advice at any time.

The range of works carried out by Verwater includes the construction of complete tank pits. The company has wide experience regarding liquid tight tank pits that comply with environmental regulations. Its work may involve new construction or the rehabilitation of existing tank pits and is integrally linked with leak detection systems In addition to civil works inside the tank pit Verwater also undertakes total infrastructural works on plants.

Part of the routine of maintenance works is taking measurements to determine deflections on the tank shell or tank shell or tank bottom. These deflections can occur as a result of soil settlements. Three types of surveys are made to determine whether the tank meets the requirements; a horizontal survey of the tank shell, a horizontal survey of the tank shell, a tank bottom level survey and an out of roundness survey. To process these surveys Verwater developed special software programs that display the results both visually and numerically.

The Civil Works department of Verwater of Verwater specializes in tank foundation construction, construction and concrete works. A total package that consists of soil investigation and the installation of drainage, sewerage, pipe tracks, bundwalls, liquid separators and sand trap pits. To carry out maintenance on existing tank foundations Verwater gets underneath the tank after it has been jacked. A special job, but with highly skilled personnel and special equipment Verwater ensures a quick, safe and effective repair of the tank foundation.

Verwater offers a wide range of soil protection products that comply with the environmental regulations known as secondary containment. HDPE-liners are often placed under storage tanks to protect the subsoil. This material offers good chemical resistance and also has an interesting price quality ratio. Besides HDPE – liners Verwater installs other types of containment applications depending on the resistance against the stored product. The application of mineral layers are part of our package.

Concrete constructions are an in- house expertise of Verwater. Specifically foundation works for tanks and pump pits, floors, walls, column bases and piling works. This division offers sustainable solutions for pilling and foundation works.

In the field of maintenance tank jacking is a specialism which cannot be missed , as it gives opportunities for mechanical tank repairs up to complete tank refurbishments. Thousands of hanks have safely been jacked and repaired with the Verwatwe Tanknology , showing the reliability of the system .No matter what size or type , there is a hacking method available for every tank.

Different jacking methods:

There are a number of reasons to why tanks need to be lifted . A common reason is settlement. Verwater’s tank jacking technique makes restoring the original levels of the tank a simple job. To carry out repairs on foundations the treatment of leakages jacking is the most effective way to get underneath the tank.

Verwater is a specialist in tank relocations. Combined with jacking techniques the company has solutions for shifting tanks of any type and any size. Verwater guarantees the integrity of the tank and its continued life span.

There are various reasons for relocating tanks. More stringent requirements from the authorities or a modified layout of the tank farm can make companies decide to relocate tanks. There is a wide variety of tank relocating techniques. Tanks can be rolled on skidtracks, lifted and moved by using a combination of there techniques that are all mastered by Verwater. The company invests in innovations, making sure the safest and most efficient techniques are used now and in the future.

Verwater is the right partner for total terminal construction project. The coordination of the complete project is with one contractor only, simplifying cost management and project planning. Verwater utilizes this total construction package worldwide. Experienced and skilled people on site ensure the customer with a safe and sound operational facility for years to come.

The construction of tank bottoms, shells and rooftops are part of the scope of the construction division, as well as the construction of related components such as windgirders, heating elements and pipe connections.

Tank erection is a core competence at Verwater. There are a number of ways to erect tanks. All of the different methods are being used by Verwater. The company often chooses for the jacking method. Verwater has developed its own unique jacking system for tank construction, guaranteeing a fast and solid jacking method. This makes the jacking method a safe and efficient procedure.

The stacking method is another expertise of Verwater. Depending on the circumstances conventional stacking can be a better alternative. The type and proportion of the tank or the infrastructure around the tank influence the choice of method made by Verwater. If jacking is not an option, Verwater switches to the stacking method. With the highest safety standards in consideration and efficient planning on site, this method meets the quality standards Verwater aims for.

Verwater constructs prefabricated tanks as well. Small tanks and pressure vessels are made in Verwater’s own workshop. Highly skilled workers are able to deliver products that require specific specifications.

Every tank needs its unique roof, seal or dome. Verwater is an experienced partner when it comes to the construction and installation of tank roofs and seals. At Verwater roofs and seals are part of the construction package, making costs and efficiency more controlled.

The piping division of Verwater is specialized in all kinds of piping and mechanical works. From the design , procurement , prefabrications until the construction on site . Verwater offers a full package for the storage and petrochemical industry .In fact all fluid processing companies are potential working areas for Verwater .

The piping services of Verwater include , but are not limited to the following materials :

Greenfield and brownfield piping are specialisms of Verwater’s piping division. Mechanical projects including concrete and structural works are carried out by Verwater. By working together with Verrwater’s other disciplines the piping department is able to offer complete pipe installations, including all supporting elements such as structural steel and related civil works. This way all activities are managed by Verwater, making the construction process as efficient as possible.

In addition to on site construction, Verwater has workshops for prefabrication of piping works and specials . The design , engineering , construction and installation are all carried out by Verwater’s skilld piping division .Specials such as skids , strainers , pulling , heads for the offshore industry , pressure vessels and headers , are all part of Verwater’s services. To operate the high-tech machines in our workshop , experienced professionals are in – house available.

The focus of the piping and mechanical division of Verwater is mechanical maintenance. This is often based on long term partnerships with our clients. Besides all piping and mechanical maintenance, this includes mechanical turnarounds and shutdowns and turnarounds ; bundle pulling, cleaning, inspection and repair by plug in or replacing. Also dismantling, cleaning, inspection and repair of repair of reboilers are in the scope of the piping and mechanical division. Mostly all the mechanical works on ovens and distillation columns are executed by our own experienced employees.

Aging, damaging and corrosion of surfaces are likely to occur due to the climate or other specific circumstances. The special coating division of Verwater, P.C.C. Conserveringswerken, has the solution for every surface problem. Verwatwe’s specialists use different techniques depending on the surface material and structure.

The painting works consist of wide range of activates. The preparations begin by applying primers and different additional layers to make the surface ready to withstand harsh weather conditions or a difficult climate.

Highly skilled professionals are able to offer divergent services .Some of these specialisms include :

Every job requires a specific technique , a technique that is within the scope of Verwater.

To ensure the coating process is carried out in an efficient way professional equipment is essential.

Special trucks , high pressure cleaners and blasting machines are just a few examples of the wide range of equipment that Verwater has in- house . By following the latest developments in the field of coating works Verwater wants to fulfill a pioneering role . Whether it is about safety measures or new application techniques , Verwater wants to offer a total service that meets modern and innovative coating standards.

NOVA Terminals, The Netherlands

Construction including all piping, structural, E&I,pumps, civil works and jetty

NuStar Terminal, St. Eustatius

Engineering & Construction

Vopak Terminal Europoort, The Netherlands

Tank pit, foundations, construction of heating coils and coating

MOT Maasvlakte Oil Terminal, The Netherlands

Construction with external floating roofs, civil and pipingworks

P.O.Box Muscat, Postal code,

Sultanate of Oman

Tel : +968 2460 2721

Fax : +968 2460 2714

Email : verwater@shanfari.com